Plastics are synthetic materials made from organic polymers. These materials are composed of large, repeating molecules known as monomers. Polymers are formed through a process called polymerization, where monomers bond together. Plastics are widely used in various industries due to their unique properties, such as lightness, resistance to corrosion, insulation, and moldability.

The production of plastic involves several stages, including:

Due to their unique characteristics, plastics have a wide range of applications in various industries. Some key applications include:

Plastic products include a wide range of items used in everyday life and various industries. Some common plastic products are:

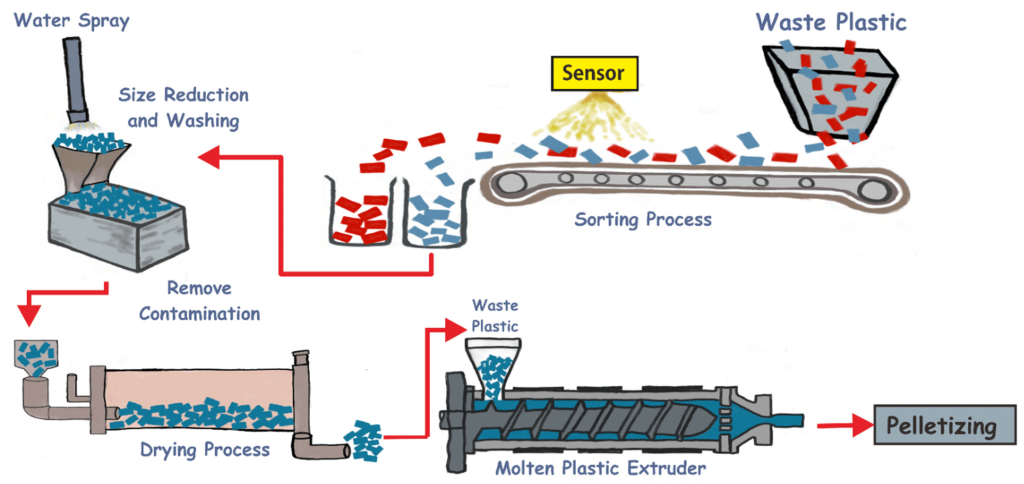

Recycling plastics is a crucial step in waste management and environmental conservation. The recycling process involves the following steps:

Recycling plastics helps reduce the consumption of raw materials, save energy, and minimize environmental pollution. Additionally, recycling reduces landfill waste and conserves natural resources.

Plastics are highly useful and versatile materials widely used in daily life and various industries. Their production starts from raw materials like oil and natural gas and involves several processes to create final products. These products find applications in packaging, automotive, construction, household appliances, and more. Recycling plastics plays a vital role in environmental protection and sustainable resource management. Given the benefits and extensive applications of plastics, developing new methods for their production and recycling is essential.

Plastic bags are widely used in various industries due to their lightweight, durability, and versatility. These bags come in different types and with various features to meet the diverse needs of users. Below is an overview of different types of plastic bags:

Features: Durable, lightweight, and highly flexible.

Applications: Carrying food items, store, and supermarket products.

Advantages: High resistance to tearing and puncturing, low cost.

Features: Soft and flexible, clear and glossy.

Applications: Packaging food items, medical and pharmaceutical products, trash bags.

Advantages: High printability, and resistance to moisture and chemicals.

Features: Lightweight, transparent, and chemically resistant.

Applications: Packaging food products, clothing, and industrial items.

Advantages: High heat resistance, recyclable.

Features: Made from biodegradable materials, eco-friendly.

Applications: Packaging food items, agricultural products, and shopping bags.

Advantages: Rapid biodegradability in the environment, reduces plastic pollution.

Features: Contains air bubbles for product protection.

Applications: Packaging electronic items, glass, ceramics, and fragile items.

Advantages: Absorbs shock and reduces damage during transport.

Features: Equipped with a zipper lock for easy opening and closing.

Applications: Packaging food items, storing small objects, chemicals.

Advantages: Reusable, maintains freshness, prevents leakage.

Features: Capable of removing air from inside the bag for better preservation.

Applications: Long-term storage of food, packaging clothing, and household items.

Advantages: Maintains freshness and quality, and reduces packaging volume.

Features: Can shrink under heat to create a tight package.

Applications: Packaging food items, electronic devices, and industrial products.

Advantages: Excellent protection against moisture and dust, extends shelf life.

Plastic standards encompass a set of regulations and technical requirements that ensure the quality, safety, and characteristics of plastics in production, usage, and recycling processes. These standards, developed by national and international organizations, help industries produce high-quality and safe plastic products. Below are some of the most important mandatory standards for plastics:

ASTM D3350: This standard specifies the properties of polyethylene for plastic pipes.

ISO 1043: This standard establishes identification codes for different polymers, helping manufacturers and consumers identify the type of plastic used.

ISO 9001: Quality management standard that helps plastic manufacturers improve their production processes and ensure product quality.

ISO 14001: Environmental management standard that helps reduce the environmental impact of plastic production processes.

ASTM D638: This standard specifies the test methods for tensile properties of plastics to assess the strength and flexibility of materials.

ISO 1133: This standard outlines methods for measuring the melt flow rate of polymers, aiding in the evaluation of plastic behavior in forming processes.

ISO 10993: This standard is for the biological evaluation of medical and pharmaceutical plastic materials.

FDA CFR 21 Part 177: Regulations by the U.S. Food and Drug Administration (FDA) that specify plastic materials suitable for contact with food.

ISO 11607: This standard is for the packaging of sterile medical devices and specifies the requirements for plastic packaging to maintain product sterility.

ASTM D3951: This standard specifies methods for packaging plastics for the transportation of goods.

ISO 15270: This standard provides guidelines for the management of plastic waste and recycling.

ASTM D7611: This standard establishes a coding system for identifying recyclable plastics to facilitate the sorting and recycling process.

Rastaa Development and Trading Innovators, with over two decades of experience in producing and exporting various products, is proud to announce its capabilities in producing and supplying plastic products, especially plastic bags. Utilizing advanced technologies and modern equipment, we produce high-quality plastic bags in various types, including:

Our company focuses on quality and innovation, supplying our products to both domestic and international markets. We adhere to national and international standards to produce a diverse range of plastic products that meet various customer needs. Your trust is our greatest asset, and we continuously strive to provide you with the best services and products.

To view the related products, please visit the products section.

Phone and WhatsApp: +98 912 683 5639

Office Phone (Vanak Branch): +98 21 8877 0680

Office Address (Vanak Branch): 27 Vanak Street, Unit 1, Tehran, Iran

Website: RastaExport.com

Email: Info@rastaexport.com

For product updates and other news, join the Sava Commercial Channel on Telegram.