Bitumen

Bitumen (also known as “asphalt“) is a sticky, black, and semi-solid substance derived from the distillation of crude oil or found naturally. It is mainly used in road construction and waterproofing.

Uses of Bitumen

- Road Construction: Bitumen is a binder for asphalt mixtures, providing a surface for roads and highways.

- Waterproofing: Due to its waterproof properties, bitumen is used for waterproofing roofs, floors, and walls.

- Building Industry: Bitumen is used in various aspects of construction, including asphalt production for flooring and as a protective material against moisture and corrosion.

- Oil and Gas Industry: Bitumen insulates oil and gas pipelines, protecting them from corrosion.

Types of Bitumen

- Pure Bitumen: Derived directly from the distillation of crude oil.

- Oxidized Bitumen: Produced by blowing air through pure bitumen, resulting in different mechanical and physical properties compared to pure bitumen.

- Cutback Bitumen: Obtained by dissolving bitumen in petroleum solvents, used for specific applications.

- Emulsion Bitumen: A mixture of bitumen and water, used for specific applications such as cold asphalt.

Detailed Classification

Bitumen is generally divided into two main categories: natural bitumen and synthetic bitumen. Each of these categories is further subdivided. Below are the main and important classifications of bitumen:

- Natural Bitumen: Natural bitumen is obtained from natural sources without chemical processing. These types of bitumen are extracted from natural deposits worldwide.

- Lake Bitumen (Asphalt Lake): Naturally found in bitumen lakes, such as the Trinidad Asphalt Lake.

- Rock Bitumen: Found in specific rocks such as bituminous sandstones.

- Synthetic Bitumen: Synthetic bitumen is derived from the distillation of crude oil and is primarily used in construction and road paving. These bitumens are divided into several types:

- Penetration Bitumen: Derived directly from crude oil distillation and classified based on penetration grade.

- Blown Bitumen: Produced by blowing air through pure bitumen, resulting in different mechanical and physical properties. Mainly used in coating and insulation industries.

- Cutback Bitumen: Obtained by dissolving bitumen in petroleum solvents. Depending on the solvent used, it is classified into rapid-curing, medium-curing, and slow-curing cutback bitumen.

- Emulsion Bitumen: A mixture of bitumen and water stabilized by an emulsifier. Used as cold asphalt and for specific applications such as road repairs.

- Other Classifications:

- Polymer Modified Bitumen: Produced by adding polymers to pure bitumen, improving properties such as resistance to heat and cracking.

- Composite Bitumen: A combination of various types of bitumen to achieve more desirable properties.

These classifications allow engineers and specialists to select and use the appropriate type of bitumen based on the specific needs of their projects.

Export

Exporting bitumen from Iran to various countries requires adhering to specific procedures and processes to ensure quality, safe transportation, and compliance with international regulations. Here are some ways to export bitumen:

- Packaging and Preparing Bitumen:

- Drum Packaging: Bitumen is packed in special metal drums (usually with a capacity of 180 kg). This packaging method is suitable for sea and land transportation.

- Jumbo Bags: Solid bitumen is packed in large bags (usually with a capacity of one ton).

- Polypropylene Bags: Used for polymer and emulsion bitumen.

- Choosing the Method of Transportation:

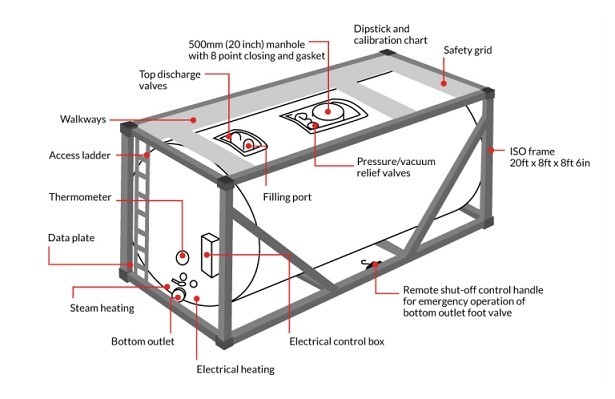

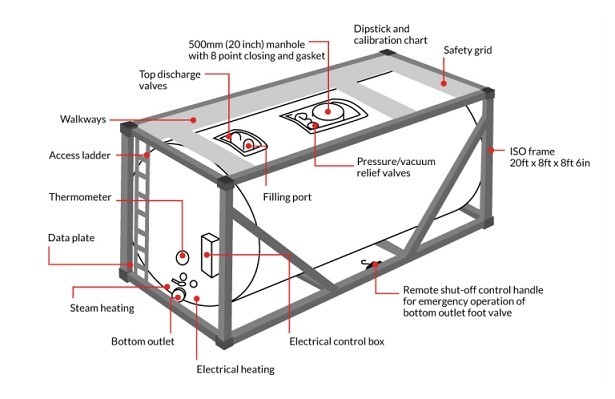

- Sea Transportation: Suitable for longer distances and large volumes, using tanker and container ships.

- Land Transportation: For neighboring countries, using special bitumen transport trucks.

- Rail Transportation: If rail infrastructure is available, bitumen can be sent to the destination using special railway wagons for petroleum products.

- Customs Procedures:

- Obtaining Necessary Permits: Includes export permits from the Ministry of Industry, Mine, and Trade, and quality standard permits.

- Paying Customs Duties: Reviewing and paying customs duties related to exports.

- Issuing Certificates: Such as quality certificates and chemical analysis certificates of bitumen.

- International Contracts:

- Setting Sales Contracts: With foreign companies to determine the terms of sale, transportation, payment, and delivery.

- Determining Payment Terms: Usually includes payment methods such as Letters of Credit (LC) or Advance Payment.

- Choosing Appropriate Packaging Method for Export:

- Drum Bitumen: Suitable for exporting to countries at longer distances and in large volumes. Metal drums can protect bitumen well and provide safer transportation.

- Jumbo Bags: Used for transporting solid and natural bitumen. These bags are highly durable and easy to transport.

- Shipping Process:

- Transport to Port: Transferring packed bitumen to the port or exit point.

- Loading: Loading drums or bags of bitumen onto ships, trucks, or railway wagons.

- Customs Clearance: Completing customs procedures at the destination and delivering the goods to the customer.

- Ensuring Quality and Compliance with Standards:

- Quality Tests: Conducting various tests to ensure bitumen quality according to international standards.

- Standard Certificates: Obtaining necessary certificates from reputable organizations to confirm the quality and standards of bitumen.

- Marketing and Creating Distribution Networks:

- Market Research: Identifying target markets and their needs.

- Distribution Networks: Creating reliable distribution networks in destination countries.

By following these steps and using appropriate methods, bitumen can be safely and efficiently exported to various countries, benefiting economically from this process.

” Related Video: Filling 190 kg Bitumen Drums “

Bitumen Standards

Bitumen standards are guidelines and specifications that ensure the quality, safety, and performance of bitumen products used in various applications such as road construction, waterproofing, and industrial uses. These standards are developed by various international organizations to provide consistency and reliability. Here are some key standards for bitumen:

1. ASTM (American Society for Testing and Materials) Standards

- ASTM D946: Standard Specification for Penetration-Graded Asphalt Cement for Use in Pavement Construction.

- ASTM D3381: Standard Specification for Viscosity-Graded Asphalt Cement for Use in Pavement Construction.

- ASTM D6114: Standard Specification for Asphalt-Rubber Binder.

2. EN (European Norms) Standards

- EN 12591: Bitumen and bituminous binders – Specifications for paving grade bitumen’s.

- EN 14023: Bitumen and bituminous binders – Specification framework for polymer-modified bitumen’s.

- EN 13808: Bitumen and bituminous binders – Framework for specifying cationic bituminous emulsions.

3. AASHTO (American Association of State Highway and Transportation Officials) Standards

- AASHTO M 320: Standard Specification for Performance-Graded Asphalt Binder.

- AASHTO T 49: Standard Method of Test for Penetration of Bituminous Materials.

4. IS (Indian Standards)

- IS 73: Paving Bitumen – Specification.

- IS 217: Cutback Bitumen – Specification.

- IS 15462: Polymer and Rubber Modified Bitumen – Specification.

5. ISO (International Organization for Standardization) Standards

- ISO 3104: Petroleum products – Transparent and opaque liquids – Determination of kinematic viscosity and calculation of dynamic viscosity.

- ISO 3838: Crude petroleum and liquid or solid petroleum products – Determination of density or relative density – Capillary-stoppered pyknometer and graduated bicapillary pyknometer methods.

6. Other Standards

- BS 3690: British Standard for bitumen and bituminous binders.

- JIS K 2207: Japanese Industrial Standard for bitumen used in road construction.

Key Test Methods for Bitumen

- Penetration Test (ASTM D5): Measures the hardness or softness of bitumen by determining the depth a standard needle penetrates under specified conditions.

- Viscosity Test (ASTM D4402): Determines the viscosity of bitumen at different temperatures to assess its flow characteristics.

- Softening Point Test (ASTM D36): Measures the temperature at which bitumen reaches a specific degree of softness.

- Ductility Test (ASTM D113): Assesses the ability of bitumen to stretch without breaking, indicating its elasticity.

- Flash Point Test (ASTM D92): Determines the temperature at which bitumen emits vapors that can ignite, indicating its volatility and safety in handling.

- Solubility Test (ASTM D2042): Measures the percentage of bitumen soluble in a specific solvent, indicating the purity of the bitumen.

Importance of Bitumen Standards

- Quality Assurance: Ensures that bitumen products meet specified performance criteria for various applications.

- Safety: Provides guidelines for safe handling, storage, and application of bitumen.

- Consistency: Standardizes the production and testing of bitumen, ensuring uniformity across different suppliers and batches.

- Performance: Helps in selecting the right type of bitumen for specific conditions and uses, ensuring durability and effectiveness in applications such as road construction and waterproofing.

By adhering to these standards, manufacturers, suppliers, and end-users can ensure the reliability and effectiveness of bitumen products in their respective applications.

About Rasta Export Company’s Capability in Bitumen Export Worldwide

Rasta Export Company is renowned for its ability to export bitumen globally, owing to the following key advantages:

1. High Quality and International Standards: Rasta Export ensures high-quality bitumen meets international standards. Utilizing state-of-the-art technology, their products adhere to stringent quality controls.

3. Global Shipping Capability: With decades of export experience, Rasta Export has the expertise to ship bitumen products worldwide. They ensure secure packaging and reliable transportation, along with necessary export documentation.

In summary, Rasta Export Company is a leading entity in the global bitumen export industry, distinguished by its commitment to quality and extensive international shipping capabilities.