Asphalt

What is Asphalt?

Asphalt is a composite construction material made from a mixture of bitumen (a type of petroleum product) and aggregate materials (such as gravel, sand, and crushed stone). Due to its unique properties, including resistance to weather, flexibility, and the ability to bear heavy loads, asphalt is one of the most important materials used in the construction of roads, airport runways, parking lots, and other surfaces.

Components

Bitumen:

– Bitumen is a sticky, semi-solid substance derived from crude oil.

– Its primary function in asphalt is to act as a binder for the aggregate materials, providing adhesion and preventing water from penetrating the asphalt structure.

Aggregate Materials:

– These include gravel, sand, and both fine and coarse aggregates.

– The aggregates act as the structural framework of the asphalt, providing mechanical strength and stability.

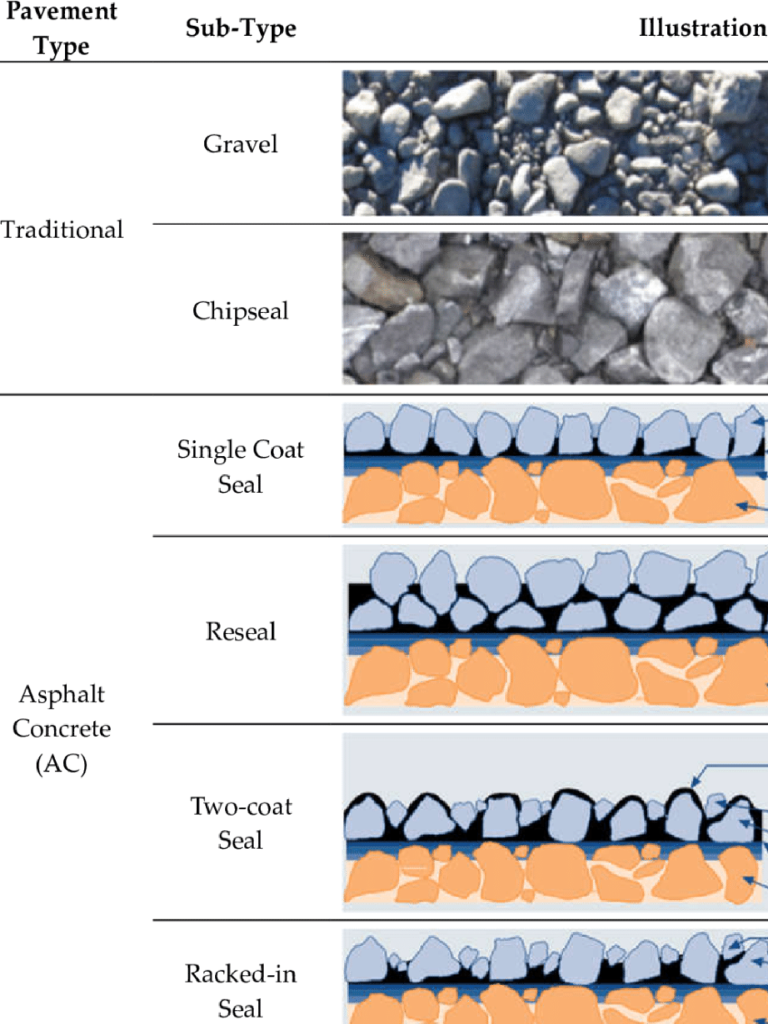

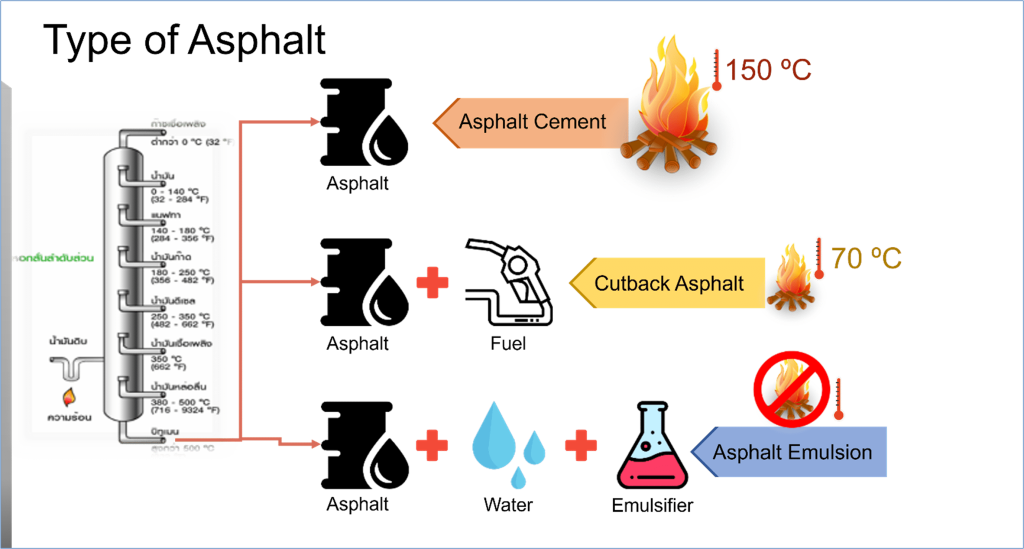

Types of Asphalt

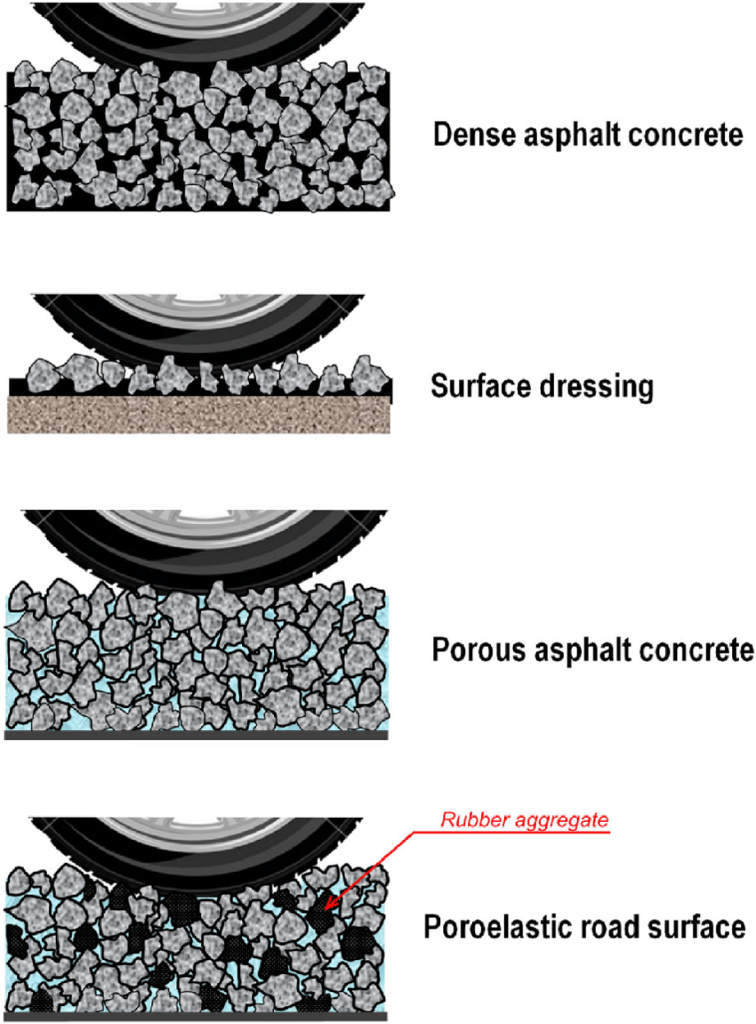

Hot Mix Asphalt (HMA):

– Description: Produced at high temperatures (around 150-180°C), HMA is known for its durability and strength.

– Applications: Main roads, highways, airport runways, and high-traffic areas.

– Types:

– Dense Graded Mixes: Suitable for all layers of pavement structure, providing good durability and structural support.

– Stone Matrix Asphalt (SMA): High-performance mix designed for high-traffic roads, offering excellent resistance to deformation and durability.

– Open Graded Mixes: Used for surface layers, providing better water drainage and reduced skidding.

Warm Mix Asphalt (WMA):

– Description: Produced at lower temperatures (around 100-140°C) compared to HMA, leading to energy savings and reduced emissions.

– Applications: Similar to HMA but preferred in urban areas due to its lower environmental impact.

– Types:

– Foamed Asphalt: Uses water to create foam in bitumen, reducing viscosity and allowing mixing at lower temperatures.

– Chemical Additives: Uses additives to reduce bitumen viscosity.

– Organic Additives: Uses waxes to reduce viscosity, enabling mixing and compaction at lower temperatures.

Cold Mix Asphalt:

– Description: Produced without heating the aggregates or bitumen, suitable for use in low temperatures and remote areas.

– Applications: Temporary road repairs, patching, and areas with limited access to heating equipment.

– Types:

– Cold Patch: For quick and temporary repairs, usually available in packaging.

– **Cold Mix Base and Surface Layers**: For constructing or repairing roads where hot mix asphalt plants are not accessible.

Mastic Asphalt:

– Description: Highly durable and impermeable, made by heating bitumen and aggregates to a molten state.

– Applications: Waterproofing, roofing, bridges, and industrial floors.

– Types:

– Mastic Asphalt for Roofing: For flat roof applications.

– Mastic Asphalt Paving: For roads and pavements requiring high durability and water resistance.

Porous Asphalt:

– Description: Designed to allow water to pass through the surface, reducing surface water runoff and improving water management.

– Applications: Parking lots, driveways, and roads in areas with heavy rainfall.

– Types:

– Porous Surface Layer: Provides good drainage and skid resistance.

– Porous Base Layer: Enhances subsurface drainage and reduces hydrostatic pressure.

Grades

Grades are determined based on the properties of the bitumen used in the mix. The grading system varies by region but generally includes:

Penetration Grade:

– Description: Based on the penetration of a needle into a bitumen sample at a specified temperature.

– Common Grades: 40/50, 60/70, 80/100.

Performance Grade (PG):

– Description: Based on the performance of bitumen under specific temperatures and conditions.

– Common Grades: PG 58-22, PG 64-28, PG 70-22.

Viscosity Grade:

– Description: Based on the viscosity of bitumen at specified temperatures.

– Common Grades: AC-10, AC-20, AC-30.

Softening Point Grade:

– Description: Based on the temperature at which bitumen softens.

– Common Grades: SP 50, SP 60, SP 70.

Recycling and Its Methods

Recycling refers to the process in which old asphalt is reproduced and reused. This method not only helps conserve natural resources but is also economically advantageous.

Recycling Methods

Cold In-Place Recycling (CIR):

– Process: In this method, the old asphalt is crushed on-site and mixed with new materials like emulsion or cement. The mix is then re-laid at the site.

– Advantages: Lower cost, shorter execution time, reduced material transportation.

– Disadvantages: Requires specialized and complex equipment, lower performance compared to hot recycling.

Hot In-Place Recycling (HIR):

– Process: In this method, the old asphalt is heated on-site, recombined, and then re-laid.

– Advantages: Improved quality of recycled asphalt, shorter execution time.

– Disadvantages: Requires specialized and complex equipment, higher costs.

Plant Recycling:

– Process: In this method, the old asphalt is transported to a plant, where it is crushed, heated, and mixed with new materials. The new asphalt is then transported and laid at the project site.

– Advantages: High quality, the ability to use a high percentage of recycled materials.

– Disadvantages: Transportation costs, and longer execution time.

Cold Central Plant Recycling (CCPR):

– Process* In this method, the old asphalt is transported to a plant, crushed, and mixed with new materials at ambient temperature.

– Advantages: Reduced energy consumption, ability to be used in various weather conditions.

– Disadvantages: Requires specialized equipment, lower performance compared to hot recycling.

Advantages and Disadvantages of Recycling

Advantages:

– Conservation of Natural Resources: Reduces the need for raw material extraction.

– Cost Reduction: Recycling asphalt is usually cheaper than producing new asphalt.

– Energy Savings: Reduced energy consumption compared to producing new asphalt.

– Reduced Greenhouse Gas Emissions: Less air pollution and environmental impact.

Disadvantages:

– Need for Specialized Equipment: Some recycling methods require complex and expensive equipment.

– Variable Quality: The quality of recycled asphalt may be lower compared to new asphalt.

– Technical Limitations: Some recycling methods may not be feasible in specific weather or geographical conditions.

Considering the advantages and disadvantages, the choice of the appropriate recycling method depends on the project conditions, budget, and available equipment. Ultimately, asphalt recycling, as a sustainable and economical solution, plays a vital role in the road construction and transportation engineering industry.

Standards

Standards are a set of criteria and requirements used to ensure the quality and proper performance of asphalt in various road construction and building projects. These standards include technical specifications, testing methods, and quality requirements for materials and the asphalt production process. Below are some of the most important asphalt standards:

International Standards

ASTM (American Society for Testing and Materials):

– ASTM D6925: Standard for determining the density and viscosity of asphalt.

– ASTM D3157: Test methods for hot asphalt.

– ASTM D4867: Tests for moisture and adhesion of asphalt.

AASHTO (American Association of State Highway and Transportation Officials):

– AASHTO T 312: Test for determining the rheological properties of asphalt.

– AASHTO T 245: Test for determining the fatigue resistance of asphalt.

– AASHTO T 324: Test for determining the performance of asphalt under various temperature conditions.

European Standards

EN (European Norms):

– EN 13108-1: Technical specifications for asphalt mixtures and materials.

– EN 12697: Test methods for asphalt, including various tests such as determining bitumen content, tensile strength assessment, and thermal properties.

– EN 1426: Viscosity tests for bitumen.

National Standards of Iran

Iran (ISIRI):

– ISIRI 11716: Standard for hot asphalt mixtures.

– ISIRI 1723: Standard for base materials of asphalt.

– ISIRI 2041: Test methods for determining the physical and chemical properties of asphalt.

Other International Standards

ISO (International Organization for Standardization):

– ISO 9001: Quality management systems, emphasizing production standards and quality control processes, helping asphalt producers maintain product quality.

– ISO 17025: General requirements for the competence of testing and calibration laboratories, used to ensure the accuracy and reliability of asphalt tests.

Export Methods

The export process is multi-stage, requiring precise planning, adherence to international standards, and the use of appropriate transportation methods. Here, we examine the steps and various methods of asphalt export:

Market Research and Analysis

Market Research:

– Identifying Target Markets: Investigate countries with high demand for asphalt.

– Competitor Analysis: Understand competitors and review their pricing and product quality.

– Demand Analysis: Analyze market demand and determine the specific needs of each market.

Studying Laws and Regulations:

– Tariffs and Taxes: Review import tariffs and taxes related to asphalt in destination countries.

– Local Standards: Be aware of quality standards and environmental regulations in target countries.

Production and Product Preparation

Quality Production:

– Adhering to Standards: Produce asphalt in compliance with international and local standards.

– Quality Testing: Conduct quality tests and obtain necessary certifications.

Packaging:

– Proper Packaging: Use durable packaging to maintain asphalt quality during transportation.

– Labeling: Include product information such as type of asphalt, weight, production date, and expiration date on the packaging.

Types of Asphalt Packaging

Bulk Packaging:

– Advantages: Easier and faster transportation, lower costs.

– Disadvantages: Requires specialized equipment for unloading and loading.

Big Bags:

– Advantages: Better protection of asphalt, reduced waste, easier use compared to bulk.

– Disadvantages: Higher packaging and transportation costs compared to bulk.

Drums:

– Advantages: High protection of asphalt, long-term storage capability.

– Disadvantages: High packaging costs, requires more storage space.

Small Bags:

– vantages: Easier transportation, suitable for small projects.

– **Disadvantages: Higher packaging costs, and larger volume of packaging waste.

Transportation Methods

Road Transport:

– Trucks and Trailers: Use appropriate vehicles for transporting asphalt to neighboring countries.

– Road Regulations: Adhere to road transport regulations to prevent product damage.

Sea Transport:

– Special Containers: Use suitable containers for transporting asphalt to distant destinations.

– Cost and Timing: Review costs and appropriate timing for sea transport.

Rail Transport:

– Special Wagons: Use rail lines and suitable wagons for transporting asphalt to countries with rail infrastructure.

– Rail Regulations: Adhere to rail transport regulations.

Customs Processes and Documentation

Documentation:

– Commercial Invoice: Provide a commercial invoice detailing the product, price, and sale conditions.

– Certificate of Origin: Obtain a certificate of origin to confirm the country of asphalt production.

– Bill of Lading: Prepare a bill of lading with transport information and final destination.

– Quality Certificates: Provide quality test certificates for the product.

Customs Clearance:

– Awareness of Laws: Be aware of customs processes in the origin and destination countries.

– Working with Customs Brokers: Use customs brokers’ services to facilitate the customs clearance process.

Marketing and Sales

Advertising and Marketing:

– Digital and Traditional Advertising: Use various advertising methods to introduce the product.

– Trade Shows: Participate in international trade shows and events.

Distribution Networks:

– Local Distribution: Establish local distribution networks in target markets.

– Collaboration with Distributors: Collaborate with local distributors to facilitate the sales process.

Financial and Risk Management

Financial Planning:

– Cost Calculation: Calculate production, packaging, transportation, and advertising costs.

– Competitive Pricing: Set competitive prices considering costs and desired profit.

Risk Management:

– Commercial Insurance: Use commercial insurance to reduce potential risks.

– Financial Risk Assessment: Assess risks related to currency fluctuations, payment delays, and transportation issues.

Introduction to Rastaa Development and Trading Innovators

Rastaa Development and Trading Innovators proudly stands as one of the leaders in the export of petroleum and petrochemical products, particularly asphalt. With a specialized and experienced team and the use of advanced technologies, the company has successfully established its position in international markets. Rastaa Development and Trading Innovators’ export capabilities in asphalt encompass various stages from production to delivery of the final product to customers worldwide.

Export Capabilities of Rastaa Development and Trading Innovators

Quality Production:

– Adherence to International Standards: Rastaa Development and Trading Innovators produce high-quality asphalt in compliance with international standards to meet global market needs.

– Quality Testing: Continuous quality testing on products ensures the highest level of quality.

Proper Packaging:

– Bulk Packaging: Easy and fast transportation of asphalt at lower costs.

– Big Bags: Better protection of asphalt and reduced waste.

– Drums: High protection and long-term storage capability.

– Small Bags: Easier transportation, suitable for small projects.

Transportation Methods:

– Road Transport: Use appropriate trucks and trailers for transporting asphalt to neighboring countries.

– Sea Transport: Use special containers for transporting asphalt to distant destinations.

– Rail Transport: Use rail lines and suitable wagons for transporting asphalt to countries with rail infrastructure.

Customs Processes and Documentation:

– Documentation Preparation: Includes commercial invoice, certificate of origin, bill of lading, and quality certificates.

– Customs Clearance: Awareness of customs processes in the origin and destination countries and using customs brokers’ services to facilitate the customs clearance process.

Marketing and Sales:

– Advertising and Marketing: Use various digital and traditional advertising methods to introduce the product.

– Distribution Networks: Establish local distribution networks in target markets and collaborate with local distributors.

Financial and Risk Management:

– Financial Planning: Calculate production, packaging, transportation, and advertising costs and set competitive prices.

– Risk Management: Use commercial insurance to reduce potential risks and assess risks related to currency fluctuations and payment delays.

Rasta Export Contact Information

Rasta Export (short for Novaran Tose’e Tejarat Rasta), established in 2007, specializes in the production, procurement, and export of industrial fuses, petroleum products like bitumen and asphalt, solar power plants, and lighting products. With a focus on quality and innovation, Rasta Export serves both domestic and international markets.

Phone and WhatsApp: +98 912 683 5639

Office Landline (Vanak Office): +98 21 8877 0680

Vanak Office Address: No. 27, Unit 1, Vanak Street, Tehran, Iran

Email: info@rastaexport.com

Telegram Channel: Sava

You can contact us to buy and sell this product

Sales consultant

Ways of communication:

|

09126835639 |

|

09399197654 |

|

Click |